We have invested internally in internationally advanced production facilities to better control the production of our products.

Currently, we have 12 production lines in our company and will reach 20 in the next two years.

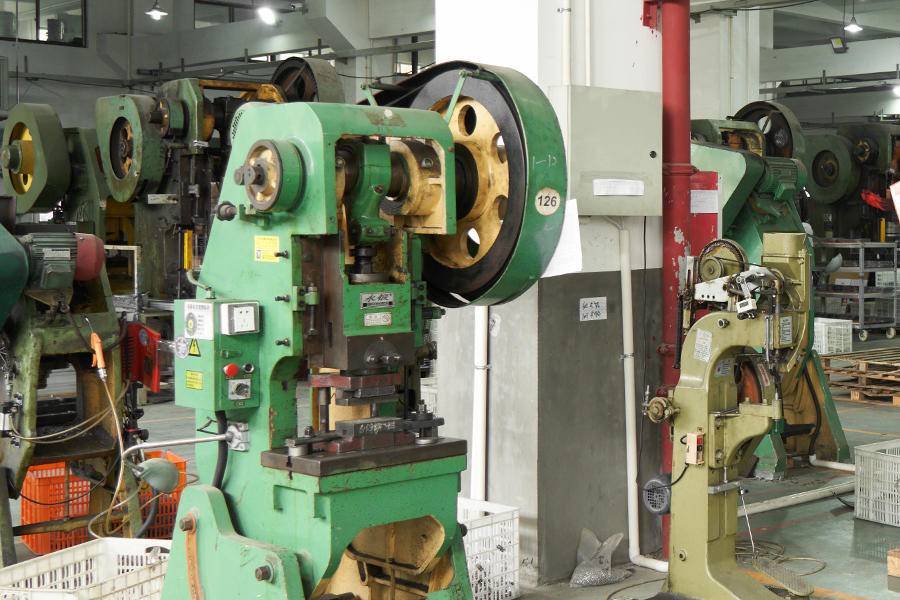

The stainless steel trim on the machine, the hardware inside the machine, and the fryer basket are all done in the hardware shop, including stamping, drawing, and final cleaning. Fryer basket part surface treatment - spray paint. Punching machine (60-200T): 42pcs; Hydraulic machine(45-200T):27pcs ; stretching machine (45T-150T):20pcs ; Robotic machine: 58pcs.

On the premise of safe production, the components that have been produced off the assembly line are assembled according to the process and quality requirements. During the assembly process, it is ensured that defective parts are not accepted or delivered, and qualified products are guaranteed to be delivered to customers.